Manage semi-finished products¶

With Odoo MRP, you can use semi-finished products to simplify a complex Bill of Materials or to represent your manufacturing flow more accurately. A semi-finished product is a manufactured product that is used as a component in a Bill of Material.

A BoM that employs semi-finished products is referred to as a multi-level BoM, where we distinguish between the top level Product and the sub-assemblies.

Configure a Multi Level BoM¶

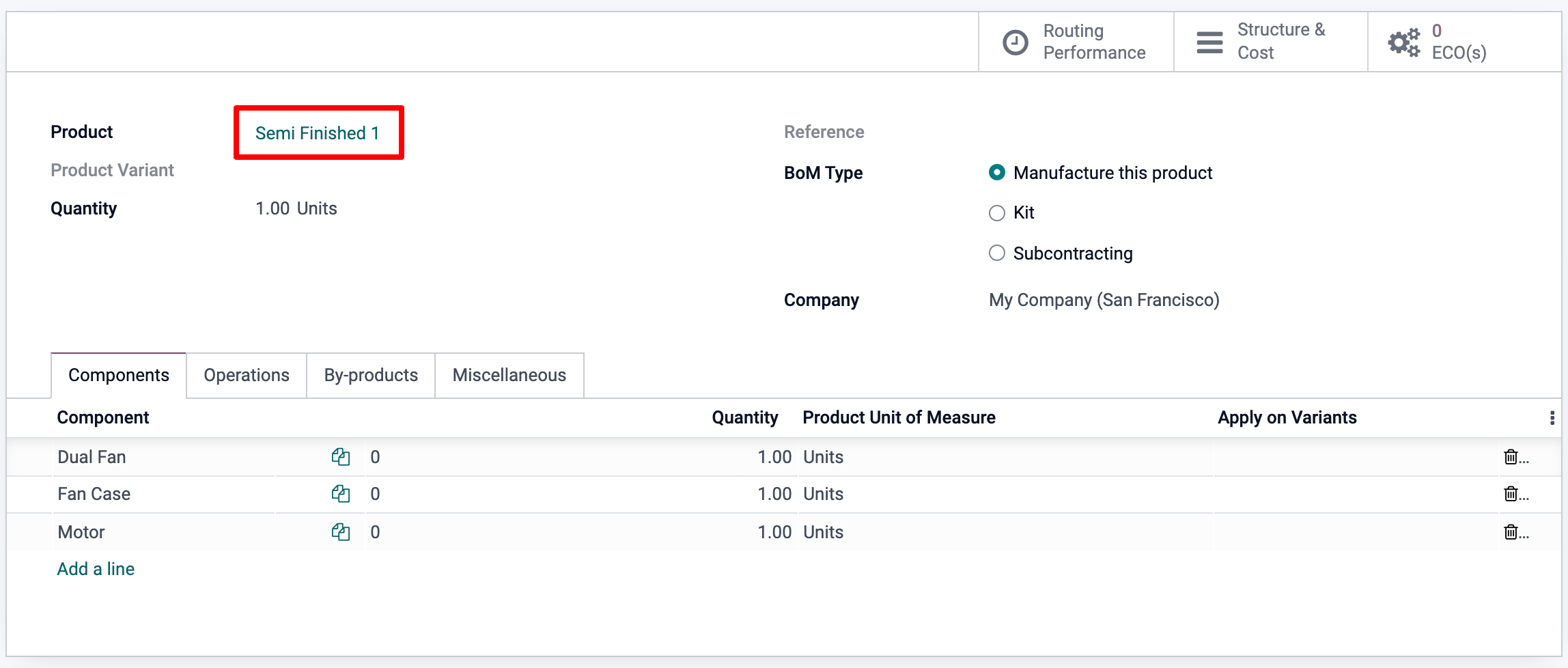

To configure a multi-level BoM, you will need the top-level product and its sub-assemblies. Therefore, you must first create the sub-assembly products and their respective Bill of Materials. Please refer to Create Bills of Materials for more details on how to create a BOM.

Configure the Main BoM¶

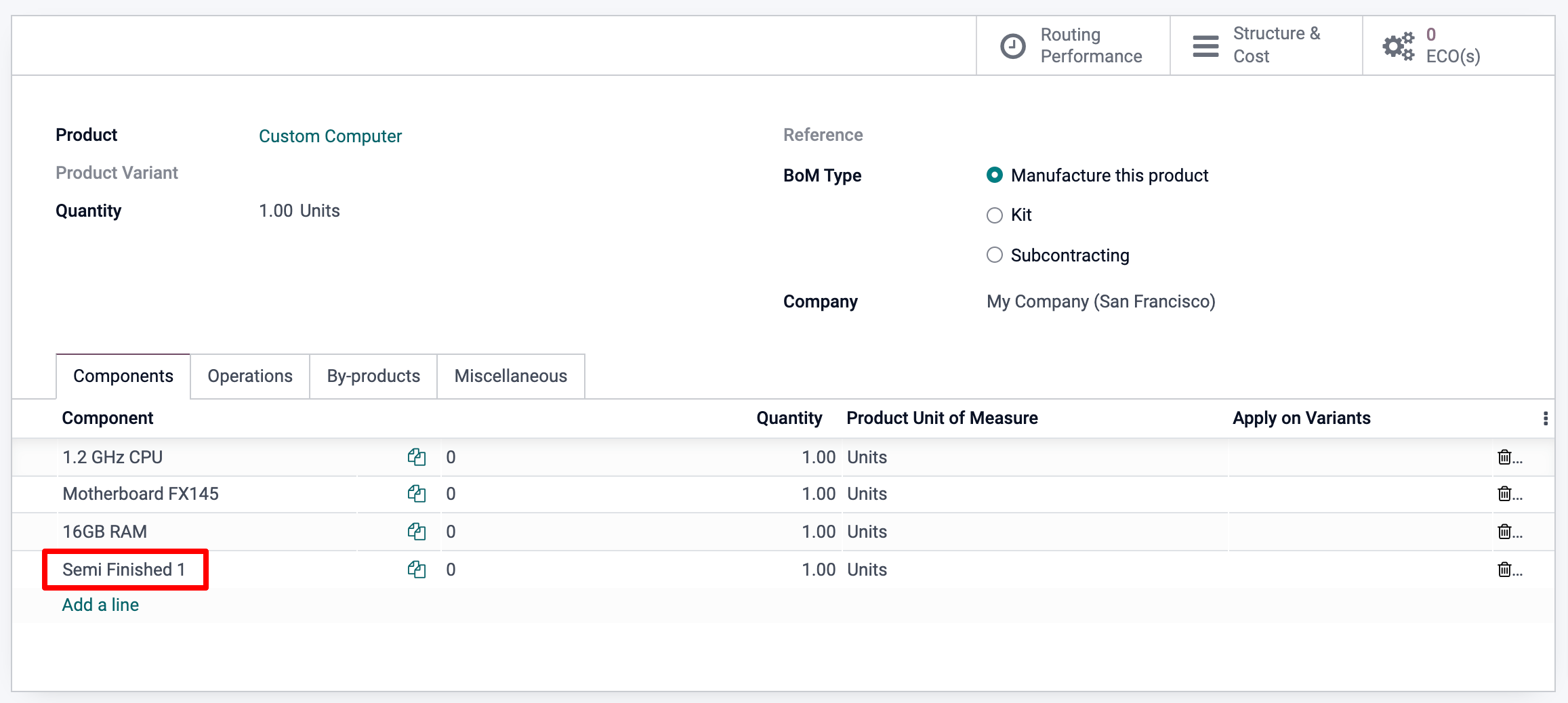

Then on the final product form, simply add your semi-finished products to the Bill of Material.

Manage your production planning¶

There are several methods to manage the triggering of the various manufacturing orders.

If every time a manufacturing order is confirmed for the main product, you’d like one for the semi-finished products as well, you have two options:

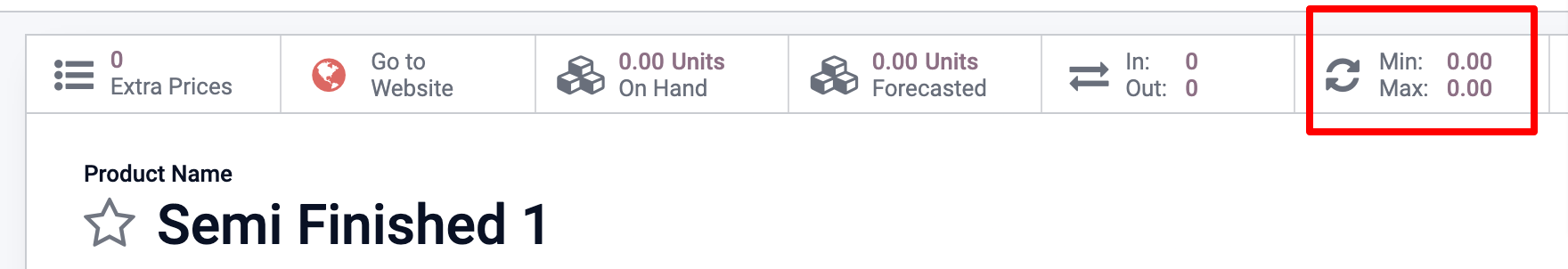

Option 1 : Create re-ordering rules for the semi-finished products, with both the minimum and maximum desired stock quantities at 0.

Option 2 : Use the Replenish on Order (MTO) route on the semi-finished product, as well as the manufacturing one.

Note that Option 1 is usually recommended over Option 2 as it is more flexible. The MTO route creates a unique link between the semi-finished and the top level product, whereas the re-ordering rule allows you to simply unreserve that production from the top level product production and redirect it to another, more pressing demand, for example.

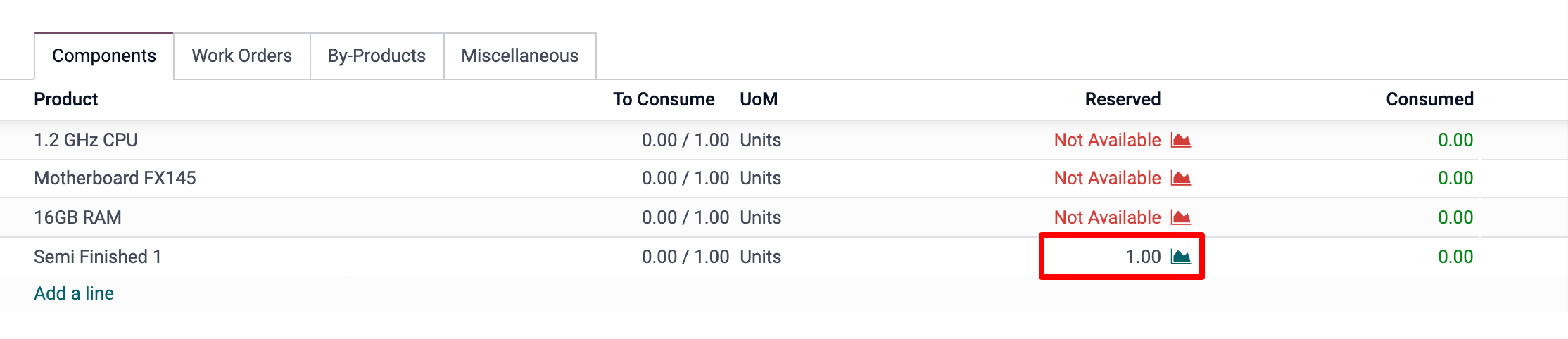

In any case, as soon as the semi-finished product is produced, it will become available in the manufacturing order of the final product, as shown below.